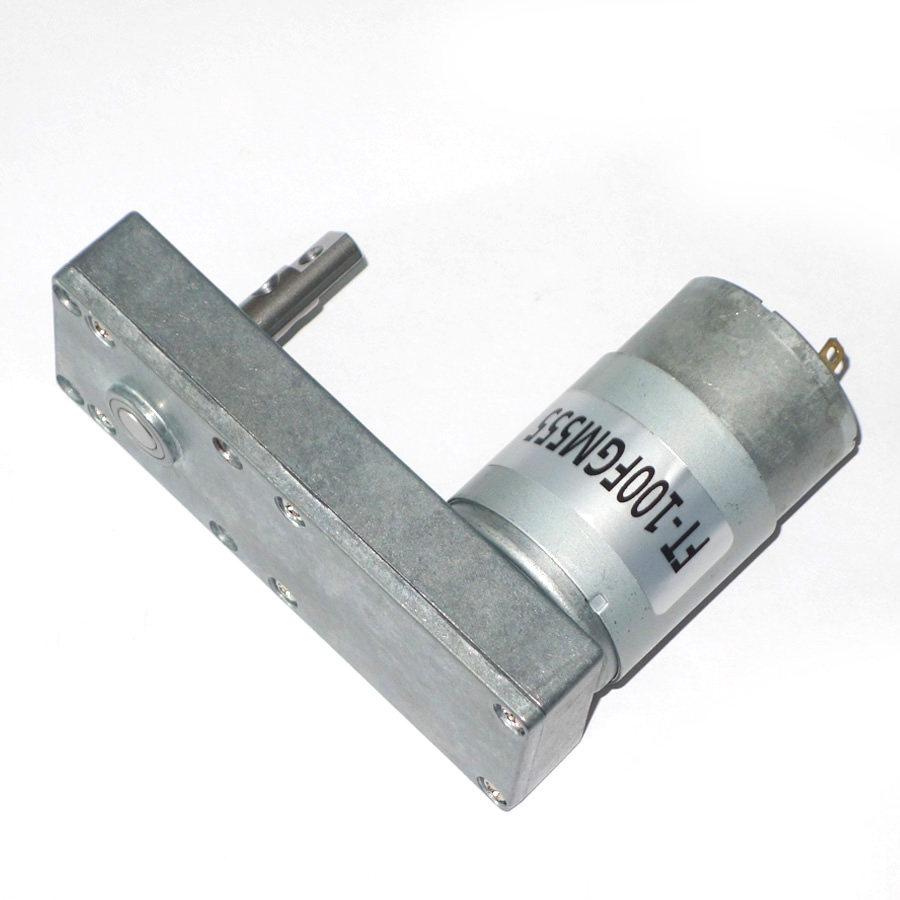

Some knowledge of domestic DC geared motors

DC geared motor is a relatively common miniature geared motor in the electromechanical industry, but there should not be too much professional knowledge about the performance and materials of the geared motor and how manufacturers choose materials, and it is not a day or two to understand. Mainly from: considering the properties of the magnetic field, considering the directionality and uniformity of the permeability of the punching piece of various gear reducer motors, considering the working magnetic density of the reducer core, considering the size of the core loss, etc., but for the selection of material structure design of foreign high-tech reducers, the understanding is not deep, so the above are some knowledge of domestic DC geared motors. 1. The geared motor is manufactured in combination with international technical requirements, and has a high scientific and technological content. 2. Space-saving, reliable and durable, high overload capacity, power up to 95KW or more. 3. Low energy consumption, superior performance, and the efficiency of the reducer is as high as 95%. 4. Low vibration, low noise, high energy saving, high-quality section steel materials, rigid cast iron box, and high-frequency heat treatment on the surface of the gear. 5. After precision machining to ensure positioning accuracy, all of which constitute the gear reducer motor of the gear transmission assembly is equipped with various motors, forming mechatronics, and completely ensuring the quality characteristics of the product. 6. The product adopts the design idea of serialization and modularization, and has a wide range of adaptability, and this series of products has a large number of motor combinations, installation positions and structural schemes, and can be selected according to actual needs at any speed and various structural forms. Speed regulation method of single-phase asynchronous induction motor The speed regulation methods of single-phase asynchronous induction motor mainly include frequency conversion speed regulation, thyristor speed regulation, string reactor speed regulation and tap speed regulation. Frequency conversion speed regulation equipment is complex, costly, and rarely used. At present, the most commonly used methods include string reactor speed regulation, tap speed regulation and thyristor speed regulation. 1) String reactor speed regulation The reactor that plays the role of voltage division is connected in series in the power supply line of the motor, and the reactance value is adjusted by selecting the turns of the reactor winding through the speed regulating switch, so as to change the voltage at both ends of the motor to achieve the purpose of speed regulation. The advantage of string reactor speed regulation is that the structure is simple and it is easy to adjust the speed regulation ratio, but it consumes more materials and the governor is large. (2) Tap method speed regulation If the reactor and the motor are combined, an intermediate winding (or speed regulating winding) is embedded in the stator core of the motor, and the magnitude and ovality of the magnetic field of the motor air gap are changed through the speed regulating switch, so that the purpose of speed regulation can be achieved. (3) Thyristor speed regulation The conduction angle of the thyristor is changed to realize the size of the AC voltage added to the single-phase asynchronous induction motor, so as to achieve the purpose of adjusting the speed of the motor, and this method can realize stepless speed regulation, and the disadvantage is that some electromagnetic interference will be generated. At present, it is often used for the speed regulation of hanging fans.

Speed regulation method of single-phase asynchronous induction motor The speed regulation methods of single-phase asynchronous induction motor mainly include frequency conversion speed regulation, thyristor speed regulation, string reactor speed regulation and tap speed regulation. Frequency conversion speed regulation equipment is complex, costly, and rarely used. At present, the most commonly used methods include string reactor speed regulation, tap speed regulation and thyristor speed regulation. 1) String reactor speed regulation The reactor that plays the role of voltage division is connected in series in the power supply line of the motor, and the reactance value is adjusted by selecting the turns of the reactor winding through the speed regulating switch, so as to change the voltage at both ends of the motor to achieve the purpose of speed regulation. The advantage of string reactor speed regulation is that the structure is simple and it is easy to adjust the speed regulation ratio, but it consumes more materials and the governor is large. (2) Tap method speed regulation If the reactor and the motor are combined, an intermediate winding (or speed regulating winding) is embedded in the stator core of the motor, and the magnitude and ovality of the magnetic field of the motor air gap are changed through the speed regulating switch, so that the purpose of speed regulation can be achieved. (3) Thyristor speed regulation The conduction angle of the thyristor is changed to realize the size of the AC voltage added to the single-phase asynchronous induction motor, so as to achieve the purpose of adjusting the speed of the motor, and this method can realize stepless speed regulation, and the disadvantage is that some electromagnetic interference will be generated. At present, it is often used for the speed regulation of hanging fans.

Navigation

Contact us

-

Service hotline0086-15989123400

- Mr. Huang:0086-15989123400

- Address:Room 802, Building 3, No.1 Huangjingpu North Road, Dalang Town, Dongguan City, Guangdong Province

Some knowledge of domestic DC geared motors