Specifications and installation methods of micro DC geared motors

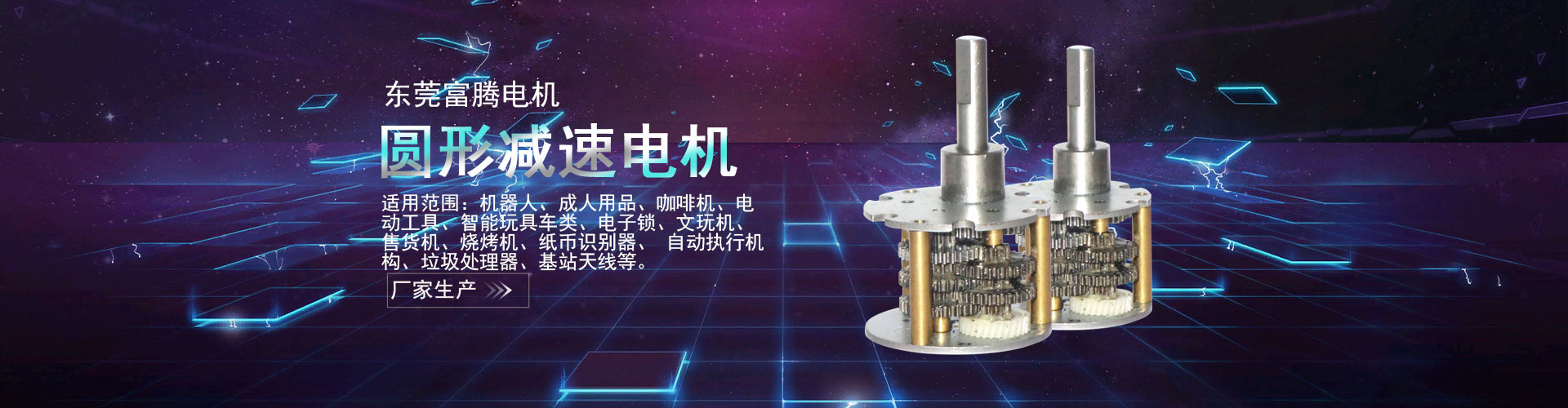

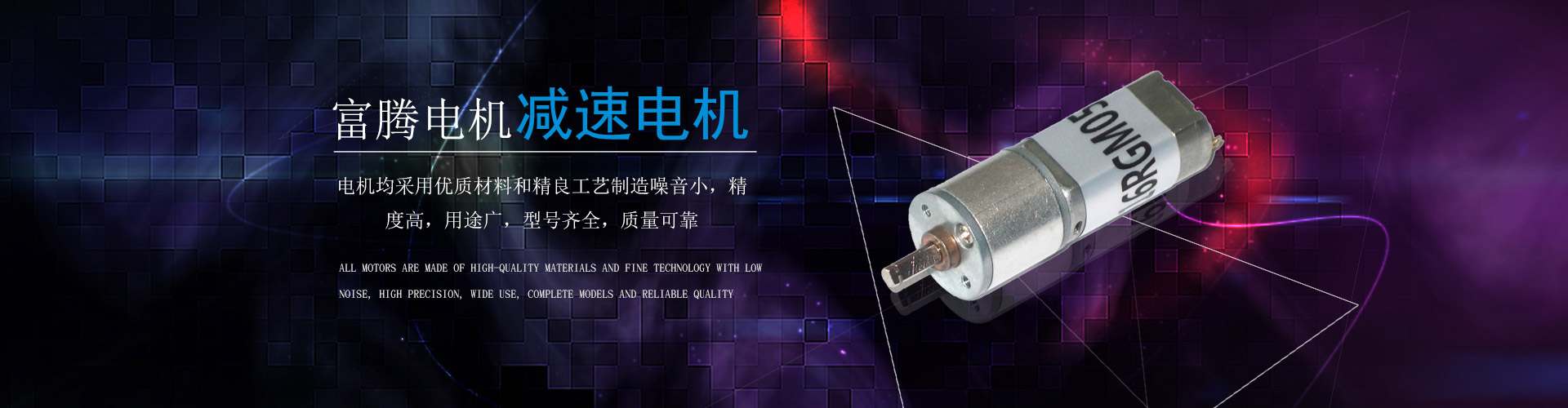

Introduction to the specifications of micro DC geared motors On the basis of ordinary DC motors, coupled with supporting gear reducers, the motor composed of is called micro DC geared motor, which can effectively improve the utilization rate in the automation industry. Due to its different uses and scope of use, it can be divided into different specifications and models: 1. NMRV series worm gear reducer motor: It is made of worm gear reducer, and various motors (including three-phase AC, single-phase AC. DC servo, permanent magnet DC motor, etc.). Smooth operation, low noise, large transmission speed ratio, strong carrying capacity. 2. PX series planetary gear reducer motor: Wide adjustment range, small size, light weight, high efficiency, compact structure, large output torque. 3. GK series square box gear DC reducer motor: The equipment is combined with perfect technology, with the characteristics of low noise and stable operation, with a reduction ratio of 3-300, with different power motors, the ideal output torque can be obtained. The installation method and principle of micro geared motor When installing the micro geared motor, it is necessary to install the correct installation steps and methods to operate, in order to ensure the normal operation of the micro geared motor equipment, therefore, before installing the micro geared motor, we must have an understanding of the installation method of the micro geared motor. Installation method of micro geared motor: 1. Before installation, confirm whether the motor and reducer are intact, and strictly check whether the dimensions of the parts connected to the motor and the reducer match, here are the dimensions and matching tolerances of the positioning boss, input shaft and reducer groove of the motor. 2. Unscrew the screws on the dust-proof hole on the outside of the flange of the reducer, adjust the clamping ring of the PCS system to align the side hole with the dust-proof hole, and insert it into the hexagon to tighten it. After that, remove the motor shaft key. 3. Connect the motor and the reducer naturally. When connecting, it is necessary to ensure that the concentricity of the output shaft of the reducer and the input shaft of the motor is consistent, and the outer flanges of the two are parallel. Before the motor is connected to the reducer, the keyway of the motor shaft should be perpendicular to the tightening bolt.

3. GK series square box gear DC reducer motor: The equipment is combined with perfect technology, with the characteristics of low noise and stable operation, with a reduction ratio of 3-300, with different power motors, the ideal output torque can be obtained. The installation method and principle of micro geared motor When installing the micro geared motor, it is necessary to install the correct installation steps and methods to operate, in order to ensure the normal operation of the micro geared motor equipment, therefore, before installing the micro geared motor, we must have an understanding of the installation method of the micro geared motor. Installation method of micro geared motor: 1. Before installation, confirm whether the motor and reducer are intact, and strictly check whether the dimensions of the parts connected to the motor and the reducer match, here are the dimensions and matching tolerances of the positioning boss, input shaft and reducer groove of the motor. 2. Unscrew the screws on the dust-proof hole on the outside of the flange of the reducer, adjust the clamping ring of the PCS system to align the side hole with the dust-proof hole, and insert it into the hexagon to tighten it. After that, remove the motor shaft key. 3. Connect the motor and the reducer naturally. When connecting, it is necessary to ensure that the concentricity of the output shaft of the reducer and the input shaft of the motor is consistent, and the outer flanges of the two are parallel. Before the motor is connected to the reducer, the keyway of the motor shaft should be perpendicular to the tightening bolt.

栏目导航

联系我们

-

服务热线0086-15989123400

- 黄总:0086-15989123400

- 地址:Room 802, Building 3, No.1 Huangjingpu North Road, Dalang Town, Dongguan City, Guangdong Province

Specifications and installation methods of micro DC geared motors